Network router specialist Vocality and contract electronics manufacturer Speedboard Assembly Services take outsourcing to a new level, through establishing a relationship under which they develop and operate lean processes to reduce lead-times for Vocality’s customers and generate growth for both companies.

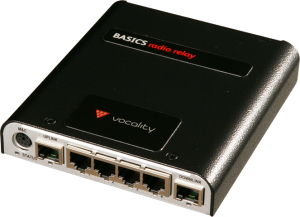

Established in the 1990s and headquartered in Surrey, Vocality is a privately-owned company specialising in network routers for data and voice. The markets it serves include aerospace, defence, security, maritime, broadcasting and the emergency services. Competition is fierce within all of these markets but the company’s commitment to investing in new technologies and supply chain processes allows it to compete successfully against much larger manufacturers.

Vocality’s products have become the solutions-of-choice for some of the world’s most demanding communications operators. Susan Harvey, Vocality’s CEO, comments: “Our success is a result of us keeping our product portfolio relevant to current and emerging industry requirements, reducing lead-times and through delivering cost-effective solutions to our customers on time, every time.”

Understandably, new product introductions (NPIs) feature strongly in Vocality’s road map, and half the company’s workforce in the UK is engaged in R&D. The remainder of its workforce is involved in sales and customer support.

All of Vocality’s manufacturing (with the exception of some final customer configuration) is now outsourced to a single contract electronics manufacture (CEM); Windsor-based Speedboard Assembly Services.

The decision to engage with just one CEM was taken in 2010, before which Speedboard was one of four that Vocality used. Harvey comments: “We evaluated all of our working practices and recognised that any cost savings we might be gaining through getting the CEMs to compete against each other were being offset by the amount of time and effort spent managing multiple manufactures and not being able to take advantage of economies of scale. We realised it would be more productive to form a much closer relationship with a single CEM.”

Of those used at the time, Speedboard alone was maintaining consistently high quality and, of equal importance, meeting agreed delivery dates. Harvey: “Which made them the obvious choice to approach about a new kind of business model.”

Customer Engineering

Richard Watson, one of Speedboard’s owners/directors and who was heavily involved in building that ‘new kind of business model’, picks up the story: “Vocality first outsourced to us in 2007 and when, subsequently, they decided to explore a new way of working we saw it as an ideal opportunity to align our documentation and manufacturing processes. We knew though it would also require us making a leap of faith. Just as Vocality was prepared to trust a single supplier and improve their documentation, we knew we would have to embrace new processes to meet their needs for significantly reduced lead-times. “

Prior to joining Speedboard, Watson worked for Lucent Technologies and was responsible for outsourcing several million pounds worth of manufacturing to the Far East. He also outsourced specialised low volume and prototype work to Speedboard; so has seen life on both sides of fence.

Over a nine-month period, Watson spent a number of days on site with Vocality, in an unpaid consulting capacity, recommending how the company’s Design for Manufacture practices should change. For example, he introduced a completely new multi-level part numbering system (to cover all of Vocality’s products and respective variants), a change note system and the rule of ‘One Bill of Materials (BOM) per product variant’; whereas previously a BOM could cover a number of variants and was therefore susceptible to misinterpretation. Watson also appraised the entire order-received-to-goods-shipped lifecycle, identifying how processes could be improved and waste eliminated, in order to provide Vocality’s customers with reduced lead-times. Based on his observations, Watson recommended the implementation of a Kanban system and that Vocality move more of the testing and final assembly to Speedboard to reduce cost and inventory.

Watson: “Through fully understanding their needs we implemented two different systems for Vocality. The first is a traditional Kanban system, for about 20 of Vocality’s products that don’t have variants. For these, we agree parameters such as Batch Size, Batch Quantity, Bin Quantity and Min/Max trigger levels. We manufacture these products, hold them in stock and deliver them on a next day Call Off basis.”

The second system is more of a Customise to Order (CTO) model, employed for about 25 of Vocality’s products that have shared baseboards. Rather than build and hold several of each product variant, Speedboard holds the shared baseboards in Kanban. When Vocality receives an order from any of its customers, it is forwarded immediately to Speedboard. It is the CEM’s responsibility to progress the build from PCBA to the required finished product variant and deliver within an agreed five-day timeframe.

The CTO model was formed out of what Watson calls ‘Customer Engineering’: “We look at what is needed for us to do the best for not only our customers but also our customers’ customers. It’s a real game-changer, but it was the only way to provide a fast turnaround on standard and customised products without holding excessive stock. Its implementation was only possible though thanks to Vocality’s willingness to let me – a supplier – come in and re-engineer some of their key processes.”

Visibility

A further benefit of the new relationship is a far more Open Book policy; and levels of transparency that just do not exist in a traditional outsourcing relationship. Speedboard provides Vocality with fully detailed manufacturing costs on a product-by-product basis. Labour costs are cited against both build and test activities, plus Speedboard provides detailed multi-level costed BOMs for each product.

Harvey notes: “From our perspective, with such a high degree of visibility over Speedboard’s costing processes it’s almost as if we have our own shop floor, supporting our day-to-day business, which gives us great control over our own pricing strategy. Accordingly, when our customers ask for a quote and an indication of delivery dates we can reply with the utmost of confidence. The level of openness also enables both us and Speedboard to monitor and, if necessary, adjust the numbers of products and boards held in Kanban to take account of forecast orders and potential product changes.”

From Speedboard’s perspective, its supply chain is also improved, and enriched with a new level of stability. Specifically, Vocality’s trust in Speedboard gives the CEM the confidence to invest in more component and finished stock than would otherwise be the case; as it is in Vocality’s best interest if Speedboard is geared to tackle larger peaks in demand.

Watson adds: “Under this new business model, both parties respect the others’ needs and constraints, and work like a single organisation. We’re also incentivised to keep reducing prices, especially if we can help Vocality secure more sales within the price-competitive marketplace in which they operate because that means more work for us. This in turn gives us the ability to seek better deals from our suppliers. It’s a real win-win.”

Harvey concludes: “We’re extremely pleased with Speedboard. We have complete confidence in their manufacturing capabilities and pricing policies. True, our organisations have their respective business objectives, but the mutual levels of trust enable both parties to focus on the development of their respective core capabilities.”

In conclusion, the levels of trust and openness established between Vocality and Speedboard are extremely rare. Under the collaboration, Vocality is trusting Speedboard to be its virtual shop floor (and keep its processes efficient and reduce costs) and Speedboard is trusting Vocality to grow its business by developing and selling products. Moreover, the relationship also challenges the proverb that you should never place all of your eggs in one basket. For if the basket is being held by two parties with a shared and vested interest in the contents, is that not that the safest way to get the eggs to market?